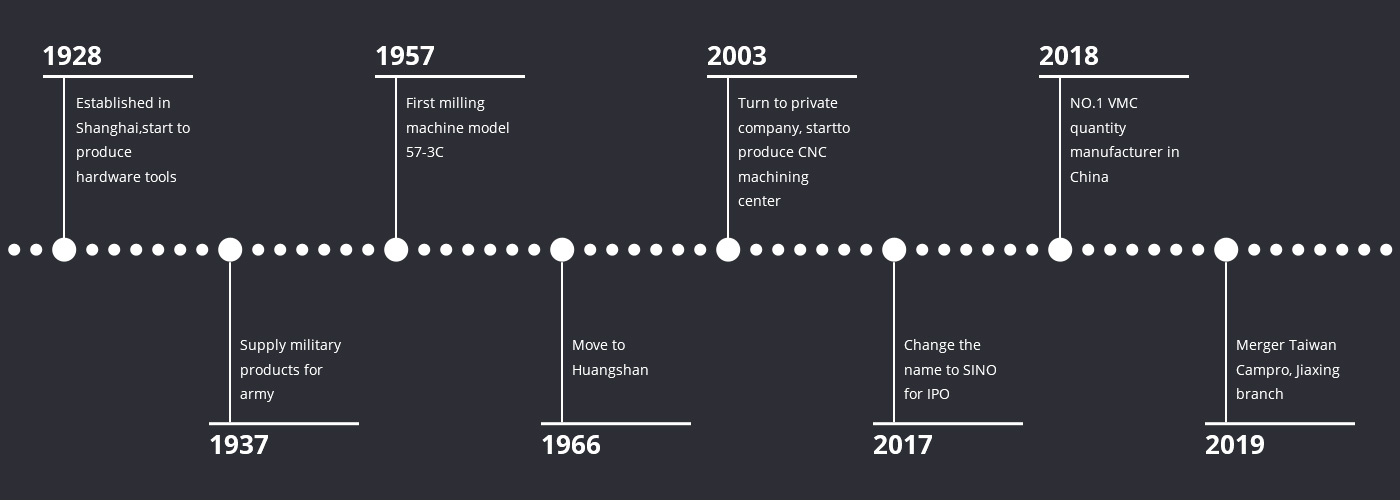

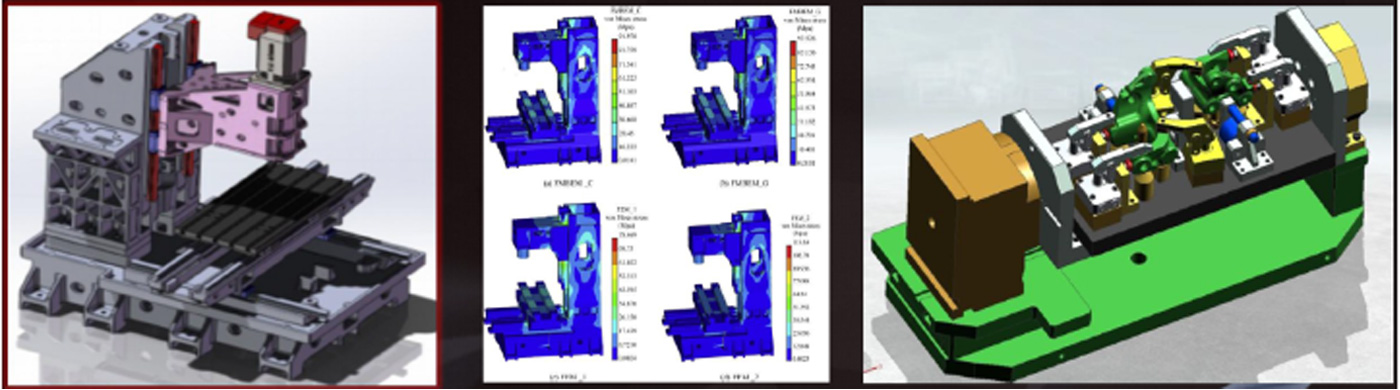

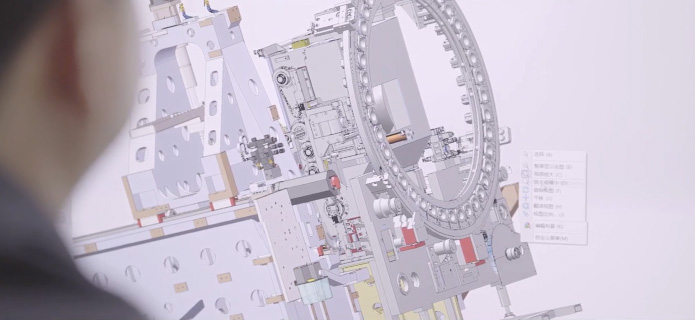

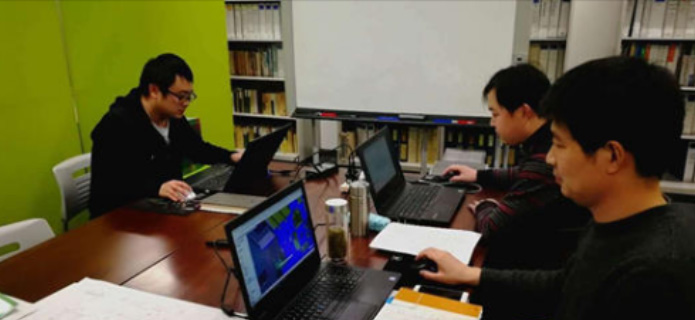

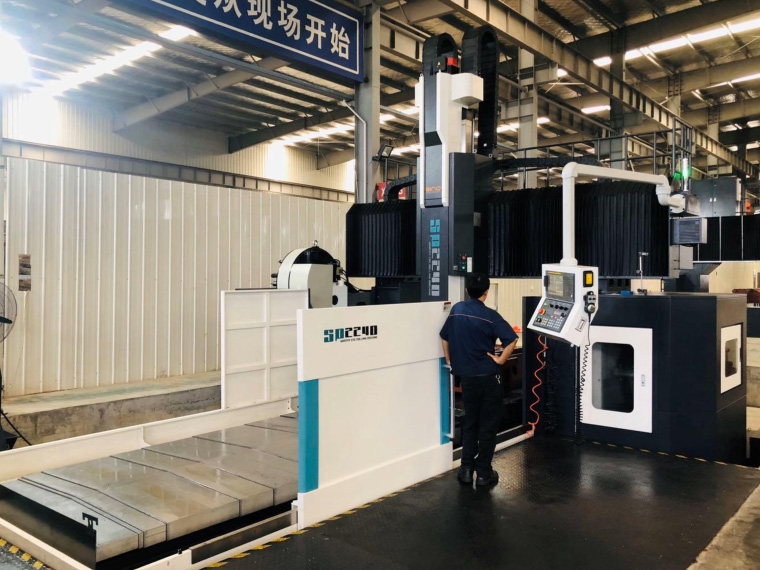

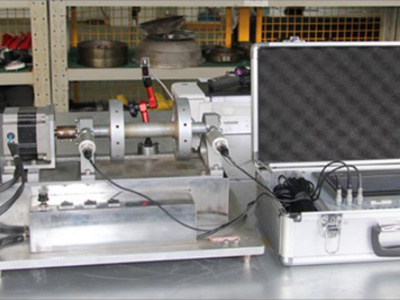

Sino Machinery Co.,Ltd. is a leading milling process solution supplier in China. It is the new name of Huangshan Wannan Machinery Co.,Ltd. who was established in 1928. Start with conventional milling mahchine, it develops into a National High-tech Enterprise which has independent R&D ability on CNC knee-type milling machine, vertical machining center, horizontal machining center and double column machining center.

Sino covers an area of 138800 square meter and locates at the world's natural and cultural heritage protected area-Yellow Mountain. People here are sincere and loyal, a lot of them devoted their whole life to accumulate technical experience and developed along with company.

"Professional, creative, efficient, philanthropic" is our company philosophy which guides us to take the rapid growth and keen creation as mission. Cooperated with Germany, Japan, Taiwan technical research institution, Sino keeps enhancing the ability on professional customization, creative R&D, efficient delivery and 7*24 hours after-sale service to meet different customer needs all over the world.

In future, we are ready to counter ever changing challenge, just like past 92 years.